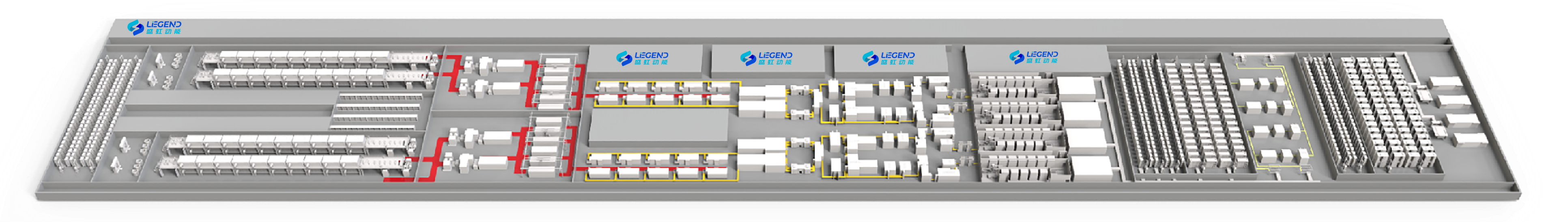

The intelligent production line of Ligend’s square energy storage module adopts cutting-edge high-tech technologies such as mechatronics integrated control, computer information processing, and automated intelligent detection, ensuring the safety and quality of the entire line while achieving intelligence.

6Quality characteristics 24 Process quality control points

1. The container is automatically transported to the workstation through AGV for assembly

2. Fully automatic nail supply and automatic tightening of PACK box fixing bolts throughout the process;

3. Large capacity bolt cache capacity;

4. Optical intelligent assisted positioning system

Please provide the following details to help our sales representativesbetter understand your needs and get in touch with you as soon aspossible

Copyright © 2024 Shenghong Ligend Power Co., Ltd. - All Rights Reserved

Legal Notice | Copyright privacy | Sitemap